Reliable Mochi Daifuku Machine Manufacturer from SWIFT

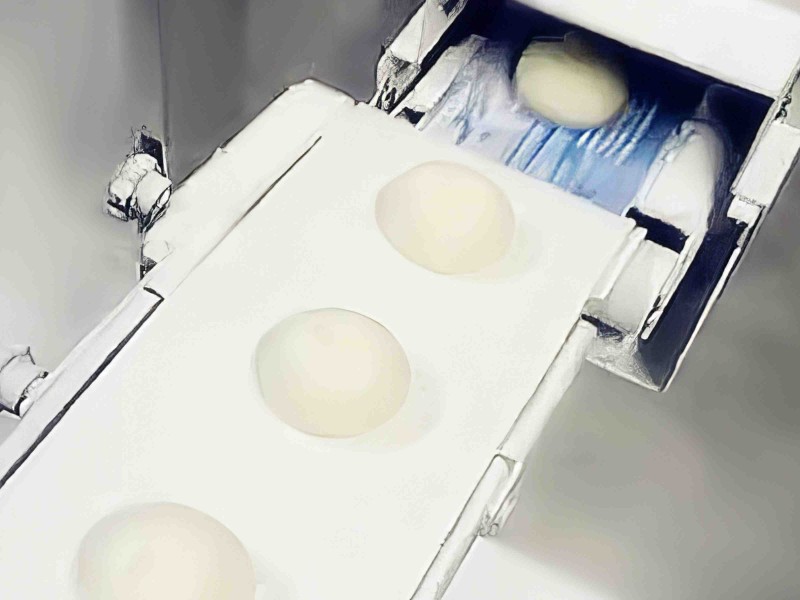

Mochi Daifuku is a beloved traditional Japanese dessert that combines chewy, sticky rice dough (mochi) with a variety of sweet fillings, such as red bean paste, fruit, or even ice cream. With its delicate texture and delightful flavors, Mochi Daifuku has gained global popularity, captivating food lovers in many countries. At Swift, we provide state-of-the-art Mochi Daifuku machines designed to streamline production, reduce labor costs, and maintain the high-quality standards your customers expect. Our machines are built with advanced technology to ensure that each piece of Mochi Daifuku is uniformly sized, with a soft, elastic outer layer and perfectly encased filling. Whether you’re producing traditional fillings or experimenting with new flavors, our Mochi Daifuku machines provide the flexibility to meet diverse customer demands.

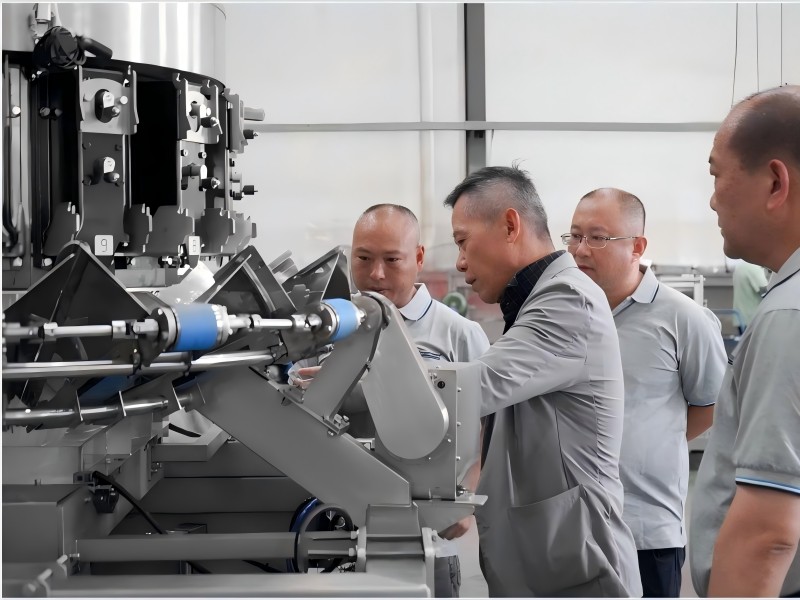

Our commitment to quality and customer satisfaction has earned us the trust of businesses worldwide. Over the years, we have helped countless food manufacturers optimize their production lines, reduce waste, and enhance the consistency of their Mochi Daifuku products. Many of our clients have experienced significant improvements in their production efficiency, with some reporting up to 30% increases in output due to the precision and reliability of our machines.

Swift Food Machinery’s Mochi Daifuku machines have become a trusted choice for businesses in the confectionery and frozen foods sectors, helping them meet growing demand while ensuring that every piece of mochi maintains the authentic taste and texture that consumers love. Whether you are scaling up production or entering the Mochi Daifuku market for the first time, our machines are designed to support your goals and help you succeed in this competitive industry.

Food Produced By Mochi Daifuku Machine

At SWIFT Machinery, we provide customized food production solutions to help businesses create high-quality mochi, daifuku, and rice-based confections with efficiency and precision. Our Mochi Daifuku Machine is designed to handle a wide variety of mochi-based products, ensuring consistent texture, perfect fillings, and customizable shapes.

Mochi Daifuku Machine Line Quality Control

Swift Machinery is committed to continuous improvement to ensure that every product we offer not only meets but exceeds our customers’ expectations.

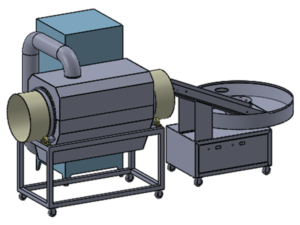

Front-end Machine

The front-end process consists of a mochi dough steamer and a mochi dough cooker, which are mainly used for the steaming and further processing of mochi dough. The steamer is heated to ensure that the dough is elastic and glutinous with long shelf life. The cooker further improves the texture and taste of the mochi dough through precise temperature control, which is suitable for the production of ambient mochi, jam mochi and other products.

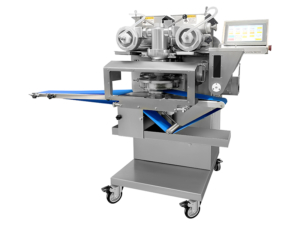

mid-section Machine

The mid-section process includes forming and coating. Automatic encrusting machine supports a variety of fillings and shapes of mochi products, such as mochi daifuku, jam mochi and so on. Powder coating machine through the adjustable conveying speed and powder coating amount, to ensure that the product evenly coated powder, suitable for sesame, cocoa powder and other powder coating materials, improve product taste and appearance.

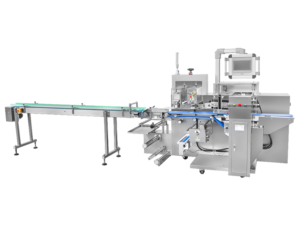

Back-end Machines

The back-end process is completed by fully automatic packaging machines, which support single-piece packaging and pouch filling packaging. The packaging machines use servo control to ensure high precision sealing and cutting, and packaging speeds of up to 20-160 bags/min. It is suitable for the packaging of ambient mochi, jam potato and other products to improve production efficiency and ensure product hygiene.