Reliable Dim Sum Samosa Shumai Machine Manufacturer from SWIFT

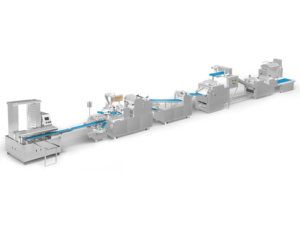

Swift’s Dim Sum, Samosa, and Shumai Machines can produce a wide range of dim sum products—from dumplings and buns to spring rolls—while ensuring consistent size, filling placement, and texture. For samosas, the machines handle the precise folding of the dough and the even distribution of fillings, ensuring a perfect crispiness when fried. Similarly, our shumai machines provide the delicate handling necessary for creating the thin wrappers and precise fillings that are characteristic of this traditional dish. With customizable settings for different fillings, dough thickness, and shaping, Swift’s machines offer the flexibility needed to meet the demands of various markets, whether you’re producing traditional dim sum or experimenting with new flavor combinations.

With a reputation for durability, ease of use, and low maintenance, Swift’s machines have become a trusted choice for food manufacturers looking to scale their operations. The user-friendly interfaces and minimal downtime make them ideal for both small-scale producers and large food manufacturers. Whether you’re focused on traditional recipes or modern variations, Swift’s Dim Sum, Samosa, and Shumai Machines are designed to deliver the quality and efficiency your business needs to stay competitive in the fast-paced food industry. Partner with Swift Food Machinery and take your production to the next level. Our reliable equipment will help you produce high-quality, consistent, and delicious dim sum, samosas, and shumai that keep customers coming back for more.

Food Produced By Dim Sum Samosa Shumai Machine

At SWIFT Machinery, we specialize in providing tailored food production solutions for a variety of cuisines, ensuring efficiency, consistency, and innovation. Whether you’re in the market for traditional dim sum, dumplings, buns, or globally inspired snacks, our state-of-the-art machinery can help you achieve high-quality results while maintaining authenticity.

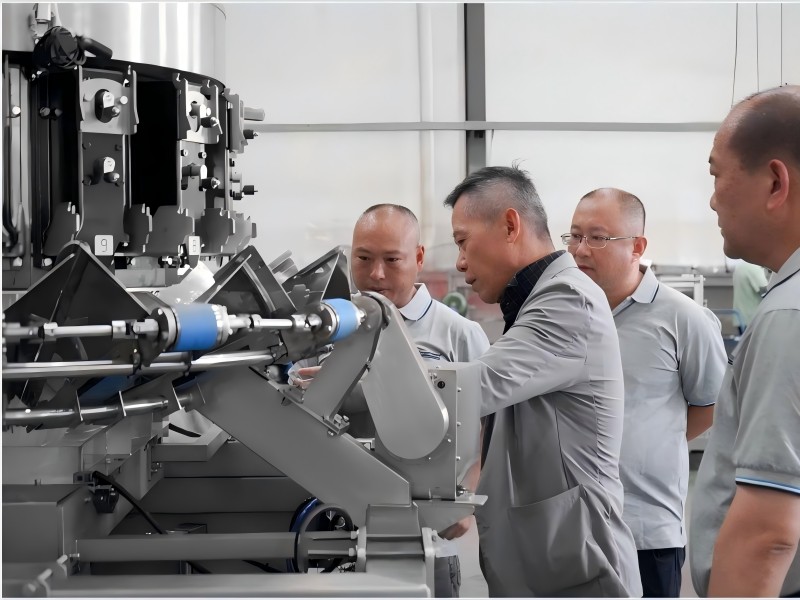

Dim Sum Samosa Shumai Making Line Quality Control

Swift Machinery is committed to continuous improvement to ensure that every product we offer not only meets but exceeds our customers’ expectations.

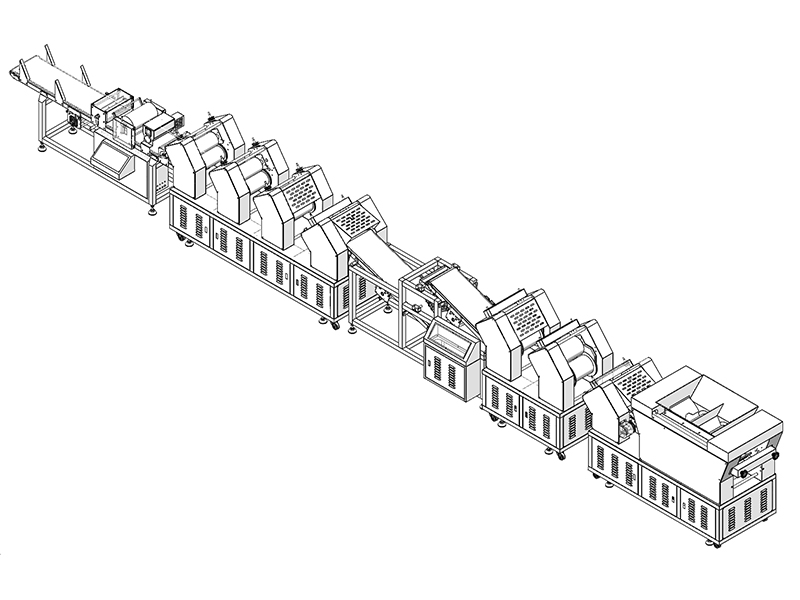

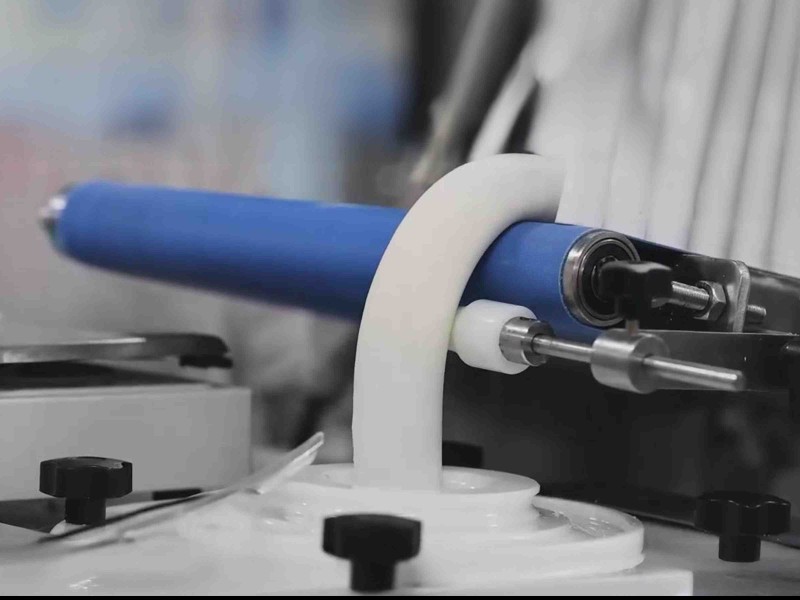

Front-end Machine

The front-end process includes kneading and pressing to ensure an even, smooth texture. The dough mixer is designed in stainless steel, in line with EU standards, and supports a variety of dough mixing, such as bread, steamed bun, etc. The dough press ensures the same thickness of dough through automatic kneading and pressing, and is equipped with safety fence and emergency switch to ensure safe operation. Efficient dough handling lays the foundation for subsequent molding.

mid-section Machine

The middle process covers the automatic molding of steamed buns, shaomai and dumplings. The equipment supports a variety of product specifications, such as siu mai, spring rolls, soup bun, etc., and the output is up to 36,000 / hour. The electromagnetic clutch and automatic alignment function ensure uniform product shape and uniform filling. Food grade stainless steel for food safety in central kitchens and food factories.

Back-end Machines

The back-end process realizes the orderly arrangement of products through the platter, which is suitable for dim sum food such as steam bun and dumplings. The equipment supports a variety of arrangements, such as parallel, staggered, etc., flexible to adapt to different sizes of baking trays and steaming trays. Efficient platting reduces labor costs, improves production efficiency, ensures neat and beautiful appearance of products, and meets the needs of large-scale production.