Reliable Croissant Machine Danish Bread Machine Manufacturer from SWIFT

Croissants, originally from France, are made using a laminated dough technique that results in a light, airy texture with golden, crispy layers. Similarly, Danish bread, with its origins in Denmark, is made from a similar laminated dough but often includes a variety of fillings such as fruit, custard, or cream cheese, offering endless versatility in flavors and shapes. These pastries require precise dough handling, perfect layering, and consistent shaping to achieve the ideal texture and appearance.

Swift’s Croissant and Danish Bread Machines are engineered to automate and optimize the production of these iconic pastries. Our machines are built to replicate the meticulous process of dough lamination, ensuring that each croissant and Danish bread is perfectly layered, with the right balance of softness and flakiness. With adjustable settings for dough thickness, folding precision, and portioning, our machines offer flexibility to produce a variety of croissants and Danish bread styles—whether you’re making classic crescent-shaped croissants or intricate, filled Danish pastries. The precision and consistency of our machines ensure that every batch of pastries meets the highest standards, reducing manual labor while increasing production efficiency.

Over the years, our croissant and Danish bread machines have helped food manufacturers around the world scale up production without compromising on quality. Additionally, the machines help reduce waste and product defects by ensuring uniformity in dough thickness, layer consistency, and pastry shape. Customers also appreciate the ease of operation and low maintenance required for Swift’s machines, which contribute to reduced downtime and improved overall productivity.

Swift Food Machinery’s reputation for providing high-quality, reliable equipment has made us a trusted partner for bakeries of all sizes. Let us help you streamline your production and elevate your bakery’s offerings with the precision and efficiency of Swift Food Machinery.

Food Produced By Croissant Machine Danish Bread Machine

At SWIFT Machinery, we specialize in providing customized food production solutions for laminated dough products, ensuring consistent quality, efficiency, and innovation. Our Croissant & Danish Bread Machines are designed to handle a wide variety of pastry styles, from traditional classics to modern, filled, and fusion pastries.

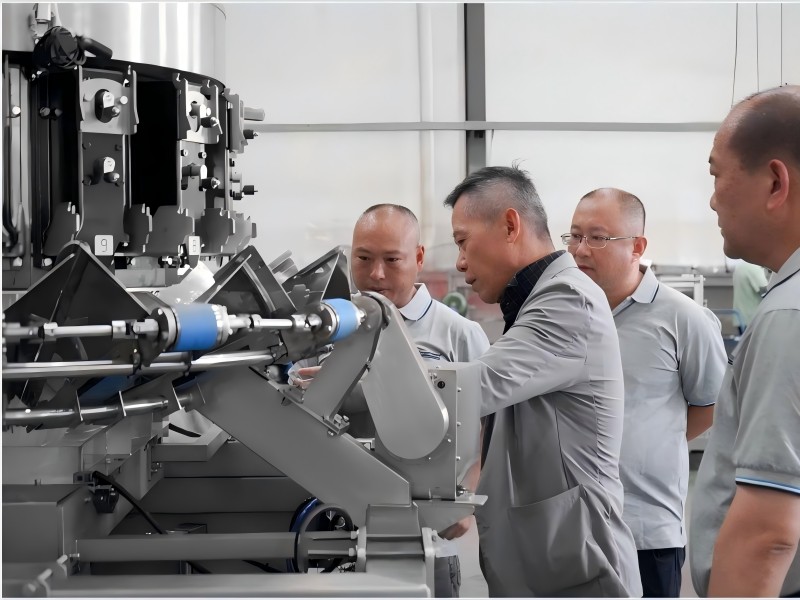

Croissant Machine Danish Bread Production Line Quality Control

Swift Machinery is committed to continuous improvement to ensure that every product we offer not only meets but exceeds our customers’ expectations.

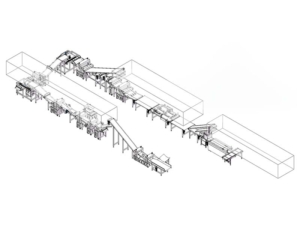

Front-end Machine

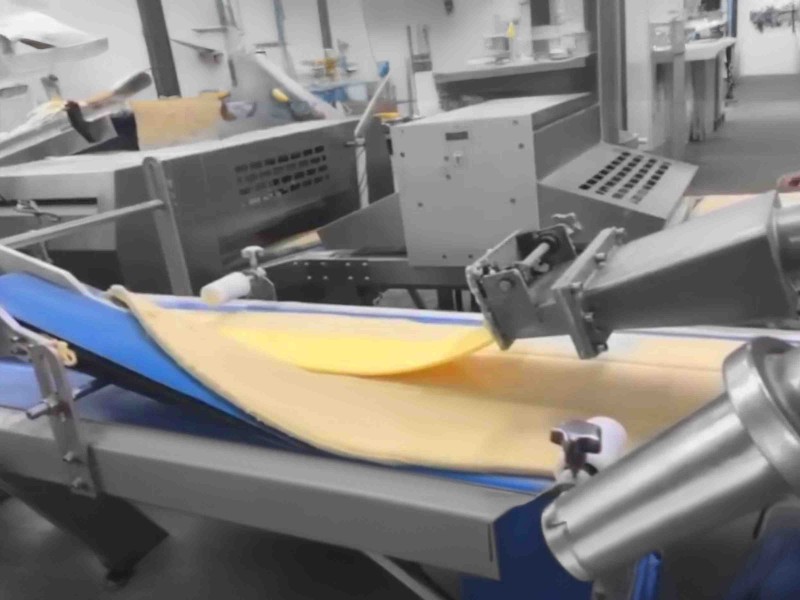

Laminating is the first step in croissant production, the key lies in the uniform treatment of dough and sheeting of layers. First, the dough is folded and pressed several times by automatic dough sheeting stations to ensure a uniform thickness and distinct layers. The pastry should be refrigerated briefly to maintain its structural stability and facilitate subsequent molding operations. The efficient completion of this step directly affects the taste and appearance of the final product.

|

Automatic Dough Mixing Kneading MachineSFT-M Series Automatic Dough Mixing Kneading Machine is for mixing kneading of croissant dough,danish bread dough, steamed bun dough, mooncake dough, cookie dough, pizza crusts, etc. |

|

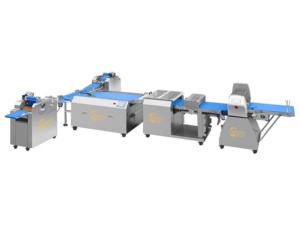

Automatic Danish Bread Frozen Pastry Dough Production LineSFT-YJ1505 Automatic Danish Bread Frozen Pastry Dough Production Line is applicable for factory production of Croissants, chocolate Croissant, Danish Pastries, Frozen Laminated Dough and other frozen pastry dough laminating sheeting and forming. |

mid-section Machine

Croissant molding is the process of cutting and rolling the pastry after sheeting. First, the pastry is precisely cut into triangles or other desired shapes by an automatic cutter. Then, the cut dough is fed into the molding machine, and the classic croissant shape is formed by rolling, folding and other operations. During the molding process, the precise control of the equipment ensures that the weight and shape of each croissant is the same. The efficient automation of this step greatly improves production efficiency and product consistency.

|

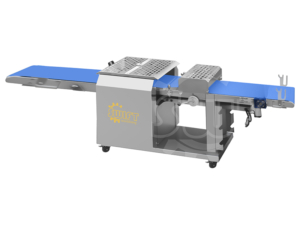

Automatic Croissant Moulding Rolling MachineSFT-NJX-640S Automatic Croissant Moulding Rolling Machine is cost-effective model of croissant machine forming line, applicable for commercial production of Croissant, Danish Bread Pastry, Croissant Donuts, and Ginger Bread Pastry. Different shapes of danish bread products can be produced by replacement of quick changing cutter system. |

|

Automatic Croissant Production LineSFT-NJX-640D Automatic Croissant Production Line is compact model of machine line, applicable for Croissant and Stuffed Croissants, Danish Bread making production. |

|

Danish Bread Pastry Cutter MachineSFT-SC640 Danish Bread Pastry Cutter Machine adopts precise servo cutting system, assure uniform size and weight of croissant products. This machine is applicable for cutting laminated dough and Ginger Bread into various desired shapes, including round, semicircular, triangular, square, and irregular shape. |

Back-end Machines

Baking and filling are the last steps in croissant production and determine the final flavor and texture of the product. First of all, the formed croissants are sent to baking oven, during the baking process, the hot air circulation system ensures uniform heating. After baking, some croissants are filled with fillings, such as cream, jam or chocolate, through an automatic filling machine. The filling process uses a high-precision control system to ensure even distribution and accurate dosing of filling.

|

Kahk Maamoul and Bread Baking OvenSFT-NFX Series Kahk Maamoul and Bread Baking Oven is applicable for Maamoul, Kahk baking, Cookie Biscuits baking, Croissant Baking, Burger Bun Bread, Tin Bread, Bread Rusk, Toast Bread and Moon Cake Baking, etc. |

|

Automatic Croissant Filler MachineSFT-F15L Automatic Croissant Filler Machine is applicable for Croissant and Danish Bread Pastry filling injection with jam, cream and chocolate filling. |