Reliable Cookies Filling Depositing Machine Manufacturer from SWIFT

Cookies are a timeless favorite in the world of baked goods, loved for their versatility in flavors, textures, and fillings. From classic chocolate chip to innovative combinations like fruit jams, nuts, and creams, cookies have evolved into an endless variety of shapes and sizes. Swift’s Cookies Filling Depositing Machines are designed to automate the process of filling cookies with precision, whether it’s jam, chocolate, or cream. The depositing system ensures that each cookie is filled evenly, reducing the chances of under or overfilling and maintaining the perfect balance of filling-to-cookie ratio for each batch. With customizable settings for filling size, dough thickness, and cookie shape, our machines offer flexibility for producing a wide range of cookie styles. This means you can cater to various market demands, offering both traditional and innovative cookie options to your customers.

The consistent quality and uniformity of the filled cookies have helped our customers maintain high product standards, ensuring that every cookie leaving the production line looks as perfect as the next. Whether you’re a small artisanal bakery or a large-scale commercial producer, our cookies filling depositing machines are built to help you meet the growing demand for delicious, perfectly filled cookies. Let us be your trusted partner in bringing your cookie production to the next level, ensuring your products stand out in a competitive market.

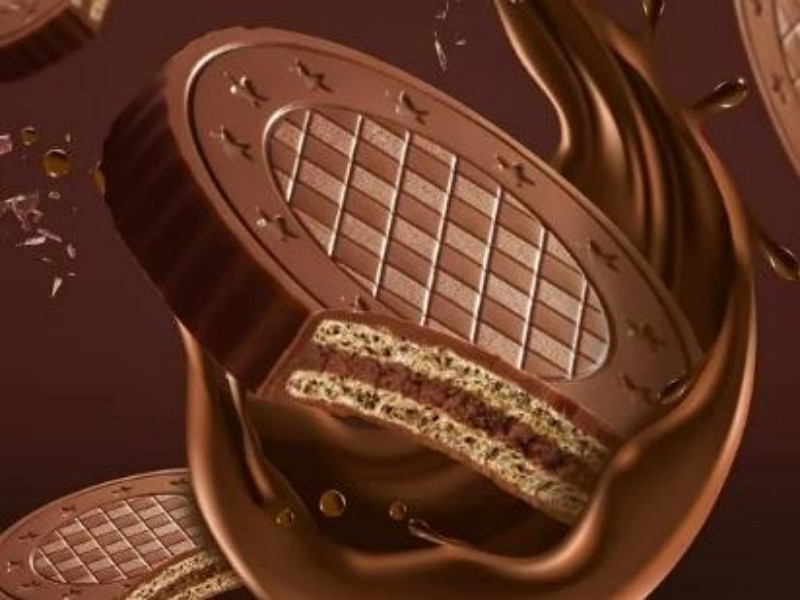

Food Produced By Cookies Filling Depositing Machine

At SWIFT Machinery, we specialize in providing customized food production solutions for cookies, biscuits, protein bars, and filled baked goods. Our Cookies Filling Depositing Machine is designed to enhance production efficiency, ensuring uniform shape, perfect fillings, and a variety of textures to meet market demands.

Cookies Filling Depositing Machine Line Quality Control

Swift Machinery is committed to continuous improvement to ensure that every product we offer not only meets but exceeds our customers’ expectations.

Front-end Machine

The front-end process is completed by a fully automatic cookie dough mixer, which is mainly used for mixing and kneading cookie dough. The mixer is made of food-grade stainless steel, meets EU standards and supports a wide range of dough types such as bread, cookies, pizza and more. The equipment is equipped with PLC touch control panel, which can adjust the mixing speed and time to ensure the uniform mixing of dough, improve production efficiency and product quality.

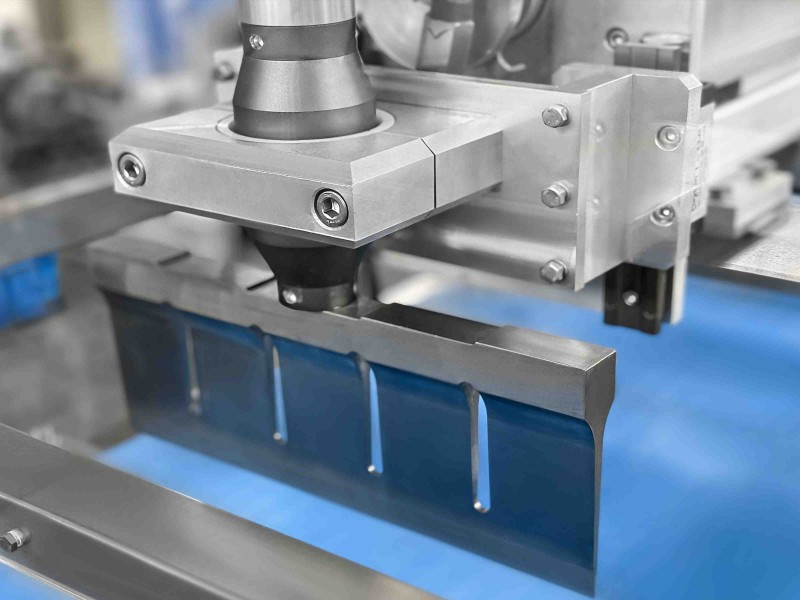

mid-section Machine

The mid-section process includes cookie encrusting, depositing and extruding. The encrusting machine supports the production of cookies with a variety of fillings and shapes to ensure an even distribution of center fillings. The depositing machine realizes the depositing molding of butter biscuits and flower-shaped biscuits through the high precision depositing system. Extrusion molding machine through the adjustable extrusion nozzle, the production of different sizes of cookie dough bites, suitable for a variety of cookie products.

Back-end Machines

The back-end process is completed by a rotary oven, which uses an efficient hot air circulation system to ensure that the cookies are evenly heated. The oven supports a variety of temperature and time Settings to adapt to the baking needs of different cookie products to ensure uniform color and crisp taste. Equipment design in line with food hygiene standards, improve production efficiency and product quality.