Reliable Maamoul Kahk Machine Manufacturer from SWIFT

Maamoul Kahk is a traditional Middle Eastern pastry that holds a special place in the hearts of food lovers across the Arab world, especially during festive occasions such as Eid. Made from a rich dough of semolina, butter, and sugar, Maamoul Kahk is typically filled with dates, nuts, or sweetened coconut, and dusted with powdered sugar for a perfect balance of flavor and texture. The delicate nature of these pastries, combined with the need for precise shaping and filling, presents a unique challenge in large-scale production. This is where Swift Food Machinery comes in, providing reliable Maamoul Kahk machines that ensure consistent, high-quality results for every batch. With features such as adjustable filling amounts, dough thickness settings, and the ability to create various shapes and sizes, Swift’s Maamoul Kahk machines provide flexibility to cater to different market needs.

Over the years, our Maamoul Kahk machines have helped countless food manufacturers improve their production capabilities. The consistent quality and uniformity achieved by our machines have allowed businesses to maintain high standards, ensuring that each Maamoul Kahk is crafted with the same perfect texture and taste, regardless of batch size. Swift Food Machinery’s commitment to customer satisfaction and product excellence has made us a trusted partner in the food industry. With a reputation for delivering high-quality, durable machines and outstanding customer service, Swift is proud to support businesses in creating the finest Maamoul Kahk products that delight consumers around the world.

Food Produced By Maamoul Kahk Machine

At SWIFT Machinery, we specialize in providing customized food production solutions tailored to meet your needs. Our Maamoul Kahk Machine is designed to produce a variety of filled pastries, ensuring high efficiency, consistent quality, and flexibility for different recipes.

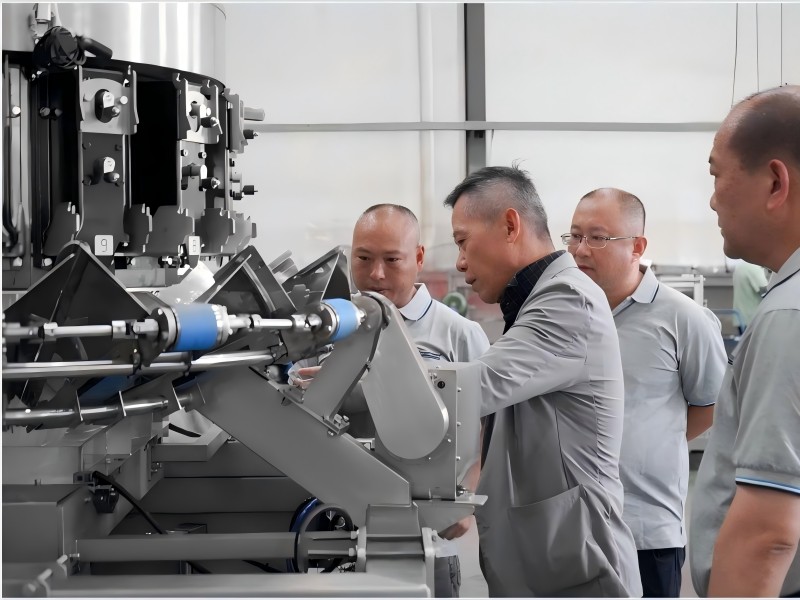

Maamoul Kahk Machine Line Quality Control

Swift Machinery is committed to continuous improvement to ensure that every product we offer not only meets but exceeds our customers’ expectations.

Front-end Machine

The front-end process is mainly completed by the encrusting machine, focusing on the production of maamoul. The encrusting machine adopts PLC control and human-machine interface to support the production of maamoul with various fillings and shapes, ensuring the uniform distribution of fillings. The equipment can adjust the size, weight and skin thickness of the maamoul, suitable for traditional moon cake, snow skin moon cake and other products, improve production flexibility and efficiency.

mid-section Machine

The mid-section process includes stamping and arranging. The stamping machine ensures the maamoul shape is consistent through precise flapping and forming technology. The panning machine arranges the maamoul neatly on the baking tray through an adjustable arrangement, supporting a variety of arrangement modes, such as parallel, staggered, etc., to improve production efficiency and reduce labor costs.

Back-end Machines

The back-end process is completed by a rotary oven, which uses an efficient hot air circulation system to ensure that the maamoul are evenly heated. Ovens support a variety of energy types, such as electricity, diesel and natural gas, to suit different production needs. Through the three-stage damper adjustment, to meet the baking requirements of different products and seasons, to ensure that the maamoul color uniformity, crisp taste.