Swift Machinery in Brief

Welcome to Swift Machinery

Shanghai Swift Machine is Professional China Food Machines Manufacturer and Supplier, our main products include Food Encrusting Filling Machine, Automatic Mochi Ice Cream Machine, Siomai Making Machine, Crepe Pancake Machine, Bread Bun Machine, Cookie machine, and Maamoul Machine, our factory provide wholesale OEM service.

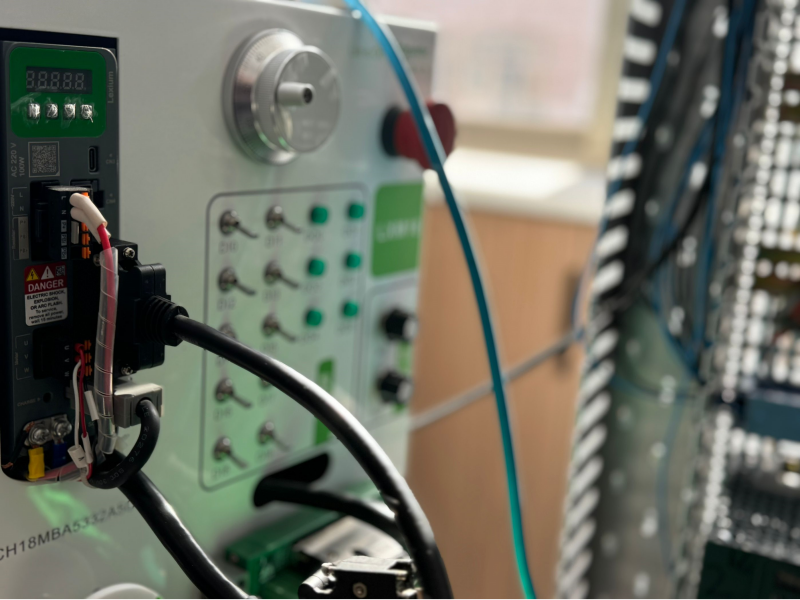

Swift has the most advanced manufacturing facilities as well as the professional designers and engineers. To increase the quality, we introduced the natural gas instead of coral. To improve machine life, we use automatic casting machine for PU. Now we have the modern facilities over 250,000 square meters. Also, we introduced the 5S Quality Control System to ensure the safety, quality and price advantage of our products.

So far, 90% of our products are exported to countries in North America, Europe, and South-East Asia area. In America, many of medium and small-sized machining workshop, electroplating workshop, parts manufacturing firm import finishing machine from us thanks to US economic recovery.

Over the years, we’ve been adhering to the business philosophy of “pioneering, innovation, integrity”, and dedicated to the development and improvement of food machinery, continue to promote technological innovation in the industry, and strive for customer service with higher quality and innovative concept, provide integrated solutions of automatic food production for global customers.

Steps To Custom Mochi Mousse Mochi Ice Cream Machine

Consultation

By understanding your needs and requirements, our salesman will work with you to submit the appropriate Mochi Mousse Mochi Ice Cream Machine solution.

Quotation

Swift expert customer service will provide you with a free quote based on your requirements as well as product specifications and quantities.

Order Confirmation

Upon receiving your order, we carefully review it to ensure that we fully understand your requirements. We then confirm the order and send you a confirmation letter.

Production

Swift has sufficient inventory and strong production capacity, and will report production progress to you from time to time.

Shipping

After strict quality control, and steady packaging, the product will be boxed. Our professional logistics team will ensure the safe delivery of goods.

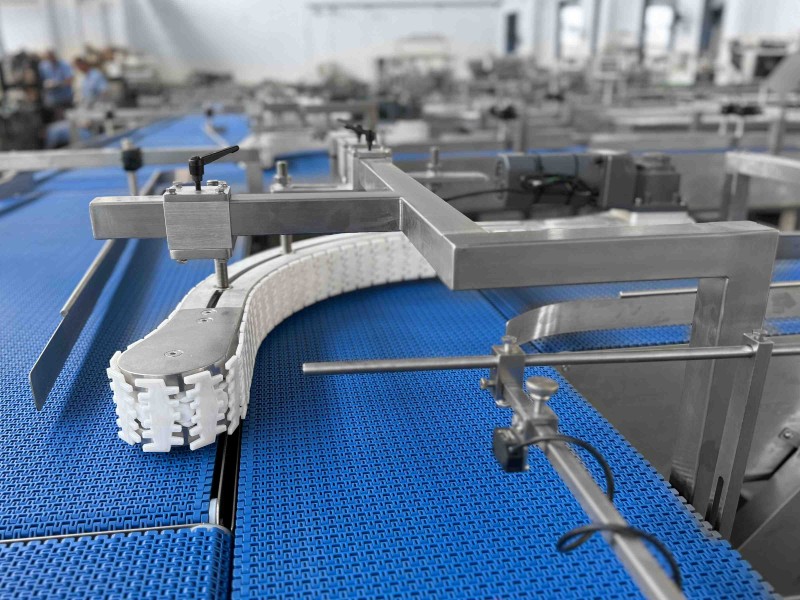

Custom Machine Line

At Swift Food Machinery, we understand that every food production facility is unique, and so are its needs. That’s why we specialize in custom whole process flow design, offering tailored solutions that ensure your production line operates at peak efficiency, safety, and consistency. From the initial concept to the final product, we guide you through every stage of the design process, ensuring that your machinery and workflow are optimized for your specific requirements.

No matter the size or complexity of your food processing needs, Swift Food Machinery is here to deliver a custom whole process flow design that helps you stay ahead of the competition. Let us partner with you to streamline your production, enhance your product quality, and achieve your business goals.

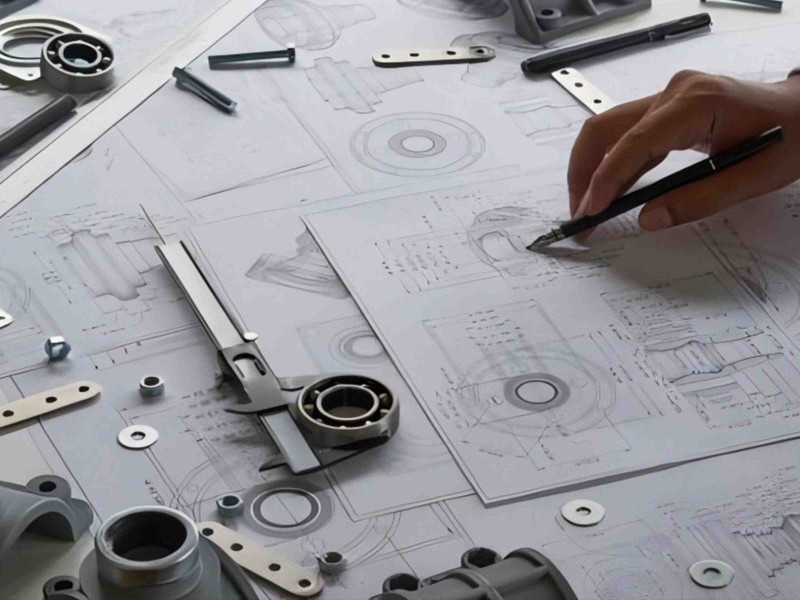

Custom Whole Process Flow Design

Our machinery design department and technology department are comprised of experienced engineers and food production equipment designers. We don’t just design for today, we design for tomorrow. Our custom whole process flow design considers future scalability and flexibility, allowing your production system to adapt to new products, higher volumes, or evolving market demands. With Swift Food Machinery, you can rest assured that your investment is built to last, and your production line can grow alongside your business.

Custom Building Layout Design & Construction Guide

We believe that the foundation of a successful food processing facility lies in a well-designed layout—one that maximizes efficiency, ensures regulatory compliance, and is flexible enough to accommodate future growth. Our layout design service is tailored to meet the unique needs of each client, whether you’re building a new plant, expanding an existing one, or redesigning an outdated facility.

Our engineers provide hands-on training, tailored to the specific equipment and machinery in your facility, to ensure that your operators are not only skilled in using the equipment but also fully aware of safety protocols, maintenance procedures, and troubleshooting. By empowering your team with the expertise they need, we help ensure smoother production processes, fewer errors, and reduced downtime, ultimately leading to increased productivity and profitability.